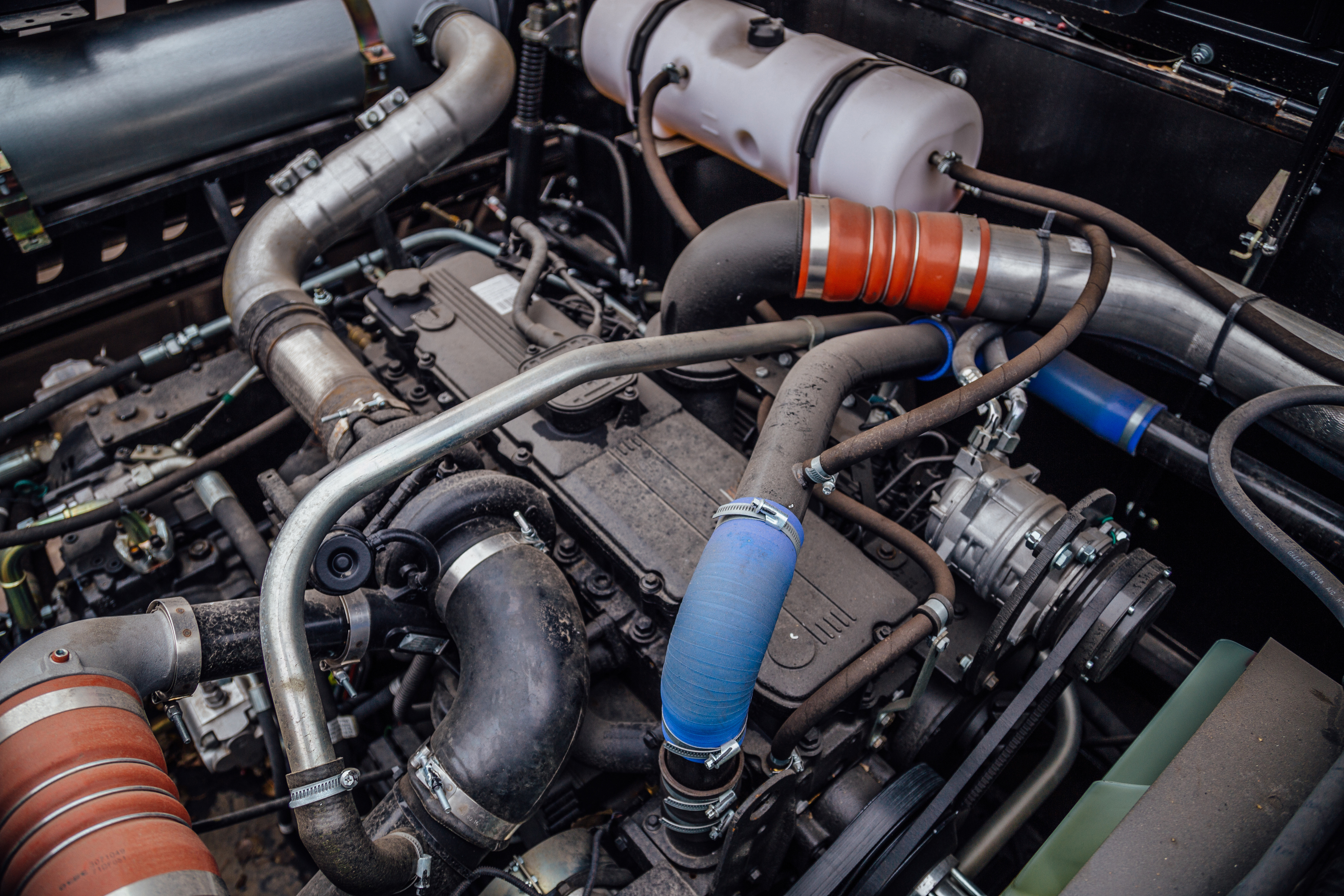

Your tractor's engine is like the heart and lungs of your equipment, and if it begins to break down or wear out, then you will lose productivity in your work. It's important to take good care of your equipment to avoid costly repairs and breakdowns. While all engines require routine maintenance, small engines are especially susceptible to problems, so it's important to perform regular cleaning and services. In this article, we will outline several steps and tips for maintaining and prolonging the longevity of your small engine.

How Do You Maintain A Tractor Engine?

While some people may overlook the need for routine maintenance on their tractor engine, it's something that should be done every two months or 200 hours of work time. Some key areas to focus on are air filter, spark plug, cooling system and oil.

Maintaining your engines will take a little time, but it will keep the equipment running smoothly and allow you to continue working for years.

Top 9 Tips To Maintain A Tractor Engine

Are you having issues with your small engine? Is it starting slower than normal or dying after being turned off? Before taking your small engine in for repairs, there are a few quick and easy steps that can be taken to see if it's something simple.

Here are our top nine tips for maintaining a tractor's engine:

- Clean The Air Filter: Your engine won't run properly if the air filter is clogged with dirt, dust and debris. When cleaning the filter, you should also take a look at the surrounding area to see if anything has become lodged in the system. This will allow your equipment to run more smoothly and improve performance. If you are looking for the best air filter cleaner, we recommend visiting your local automotive shop.

- Clean Spark Plugs And Ignition Wire Sets: The ignition wire set and spark plugs play a vital role in making sure that gasoline is ignited and turned into energy to power the engine. If you think there is any issue with this part of the engine, then you should replace the wire set. If it's only dirty, then carefully cleaning the electrodes on each plug will suffice. Keep in mind that if there is any corrosion or damage to the plugs, then they should be replaced immediately.

- Check Cooling System For Leaks And Damage: The cooling system is often overlooked when doing routine engine maintenance, but it plays a key role in making sure that the engine runs smoothly. If you are having problems with the cooling system, then you should check for any leaks around hoses or seals. If there is damage to any part of this system, you will need to have it repaired or replaced immediately.

- Always Use The Right Kind Of Oil: Using the right kind of oil is important for the long-term performance of your engine. With that said, it's also crucial to make sure that you are using the correct weight of oil. If you aren't sure what the recommended weight is, then your best bet would be to check your owner's manual or speak with a qualified professional like those at Southwest Power Equipment .

- Inspect All Belts And Hoses For Wear And Tear: Belts and hoses wear out over time due to extensive use, so take some time each month to inspect these items for any potential problems. You should also replace belts that have cracks or holes in them as soon as possible because this could lead to serious issues with the engine down the line.

- Keep The Engine Covered When Not In Use: If you work with your small engine frequently, then it may be best to take this step. Covering the equipment up will help protect the engine from any elements or debris that could cause damage down the line. You can use an indoor storage unit if you're not planning on storing your equipment outside during off season

- Inspect The Air Intake System For Damage And Obstructions: Over time, the air intake system located beneath the carburetor can become clogged with dirt and debris which causes poor performance and speeds up engine wear. If you are having these issues, then carefully cleaning out this part of the system should take care of things. If is any damage to the intake system, you will need to have it repaired or replaced.

- Always Use The Correct Fuel: Using the wrong kind of fuel in an engine can cause significant problems with performance and efficiency. Make sure that you are always using clean, fresh gasoline with added stabilizers to keep your equipment running smoothly for years to come.

- Keep It In A Safe Place: The only thing that is worse than taking a small engine out of commission is having to use it when it's raining or the temperature outside dips below freezing. Make sure you have a dry, secure place to store your equipment during these harsh conditions so they are ready to go as soon as you need them again.

These simple steps will help increase the lifespan of your engine and ensure that it is always running smoothly. If you have any questions about keeping up with routine maintenance on your engine, then make sure to ask for assistance from an experienced mechanic like those at Southwest Power Equipment . And if it's time for an upgrade, visit our website today for more information on new outdoor equipment!

Additional Tips for Maintaining Tractor Engines

Here are some additional tips to consider when performing regular maintenance on your tractor engine:

Regularly Check Oil Levels

One of the simplest, easiest ways to avoid engine failure is by checking your oil levels regularly. Ensure that you are using the recommended grade of oil for your engine - generally 10W-30 or 10W-40 depending on where you live. If it's time to change the oil, drain all of the old oil out, replace it with clean new oil and check the level again.

A lot of tractors use standard filters for their engines which makes changing them nice and easy. If your tractor uses an oil bath filter , simply look underneath the tractor to find the filter area - you'll see a round cap near this area typically. Loosen the screw by turning it counter-clockwise with your hand or adjustable wrench (be careful not to damage the screw), then pull up on the tab that is sticking out of the top to remove it completely. Now, all you have to do is remove your old filter element (it's probably stuck down in there pretty good) by pushing downward while pulling upwards at same time - just like you would to remove a stubborn jar lid. Then simply slide your new filter element in, replace the cap and tighten it by turning clockwise until snug (don't over tighten).

Take Care Of The Electrical System

Another important part of maintaining any tractor is caring for its electrical system. This is especially true if things like lights or electric start have been an issue. Batteries can go bad pretty easily so you should always try to keep yours charged up, especially before long periods of storage . Also avoid overcharging batteries because this can cause significant damage which will need to be repaired or replaced. If you notice that battery terminals are corroded, then get rid of the corrosion with a wire brush and re-tighten all connections/terminal bolts to ensure that there is no chance of a loose connection.

Regularly Check Belts and Hoses

Belts and hoses need to be checked regularly to ensure that they aren't cracking or fraying which can lead to premature failure. If you notice any damaged pieces, then replace them immediately. Otherwise, just keep an eye on them for signs of wear/tear throughout the year. You should also check your oil levels more often during this time because if any belts are slipping it could have an impact on the engine's ability to circulate the oil needed to lubricate all moving parts correctly - which will eventually wear things out much quicker if left alone.

Perform A Cleaning After Each Use

Always remember that dirt can cause havoc on an engine, especially if it becomes packed in certain areas such as around oil or coolant caps. So after each use, take the time to brush away any dirt that has gathered - just be careful not to bend any of the fins on your radiator while doing so! Also check fluid levels and add any necessary liquids like gasoline or diesel . Just make sure you run the tractor for a minute or two before doing this (or drive it around in your yard) to ensure that engine is at operating temperature and everything will flow smoothly when you fill/check them.

It's also a good idea to spray down dirty components with a hose, then wipe them down thoroughly with a rag to ensure there aren't any loose particles which could cause damage later on.

Inspecting Your Tires

Tractor tires are expensive to buy but cheap to maintain if you catch potential problems before they get out of hand. Therefore, it's always a good idea to take a look at them from time to time and check their overall condition. If you notice any cuts or punctures in the sides or tread, then it's important that these are patched up ASAP . If not, they could end up causing additional damage which will only lead to more expenses down the road - so don't take a chance with your tires!

Above all else, make sure you keep your tractor clean (especially steel components) because keeping things clean (or washing them regularly) can prevent rust and corrosion build-up.

Ensure Right Air Pressure In Tires

Most tractors have a built-in air pressure gauge that makes it incredibly easy to get the correct setting for your respective tires. This is important because improper tire pressure can lead to flats, poor handling and wear/tear on different components - so always check them before going out to mow or do any other work.

Go Through The Owner's Manual

Just as you would with a car, go through the owner's manual for your tractor and make sure that all recommended maintenance procedures are carried out at the correct time. This should be done twice a year to ensure that everything runs smoothly because it can really pay off if you do this. However, even if you don't own a tractor anymore there is no need to worry - tractors typically aren't that difficult or expensive to maintain so long as certain precautions are taken from time to time.

Obtain All The Maintenance Tools You'll Need Ahead Of Time

You can find a lot of tractor maintenance tools at your local home improvement stores, but you might not know which ones are needed - and it could be a huge waste of time/money if you just grab random things. So to avoid this problem, go ahead and purchase all the necessary tools before hand so that when that special day rolls around each year everything is ready to go. This will take some pressure off as well as ensure that nothing gets lost or thrown away by accident!

Protect The Tractor From Rain

Rain is something that most tractors are susceptible to when you're using them in wet conditions. However, if they are left out in the rain the water can cause rust/corrosion which will eat away at metal components - so always try to take them inside or cover up your tractor with a tarpaulin or plastic sheeting when this occurs. The same goes for snow, especially during the winter months - which means you might have to get creative if your tractor isn't stored inside under normal circumstances. But it's definitely worth making sure it doesn't get rained on because prolonged exposure outdoors could mean more than just some paint fading!

Check Fluids Regularly

Just like with your car, you should always check the fluids in your tractor regularly. If not, dirt and other contaminants can cause damage to components (and/or foul up certain things) which will end up costing more money over time. Luckily, these fluids are easy to access on most tractors so just spray them down with a hose/pressurize them using an air compressor before checking their levels.

Keep An Eye On Filters

Most tractors come equipped with air and fuel filters, both of which need to be inspected regularly to ensure they are clean. This is an easy process assuming you have the right tools - but there are professionals who can handle this for you as well if needed. Either way, keeping a look out for dirt/mud/dust build-up on these filters will make sure that everything runs smoothly all year round - without fail!

Lubricate Often

Just like with any car, you should lubricate your tractor on a fairly regular basis. Some components will need to be lubricated every 5-10 hours (or after specific events), whereas others may require it once or twice per month depending on how much the tractor is used/driven. However, if you don't know which parts need to be lubricated it would definitely be best to ask a professional because incorrect lubrication could do more harm than good - not to mention cause damage and increase friction (which can lead to broken/frayed belts).

Final Thoughts

If you own a tractor, it's important to perform regular maintenance on the tractor's engine to ensure optimal performance. Make sure to clean the air filter, check all fluid levels, remove debris from the cooling system, and change the oil.

Protect your tractor by covering it or bringing it indoors during inclement weather. Check for signs of wear on the tires, brakes, clutch, and more. Inspect filters for dirt and replace them if necessary. Lubricate bearings to reduce heat buildup within the engine.

A little bit of maintenance goes a long way, so make sure to pay attention to all the parts outlined above when maintaining your engine!